Safety Compliance: Terminology Matters!

In the foundry, shop terms have grown out of decades of common use. Everyone knows what a “cut-off saw,” “jib crane,” or “grinder” means in day-to-day work. The problem arises when OSHA shows up: their definitions are not the same as ours. An inspector who hears our terminology may instinctively apply a standard that sounds correct but doesn’t actually govern the equipment in question.

This isn’t about changing the way we talk in the shop. Instead, it’s about making sure managers and supervisors understand the distinctions so they can recognize when OSHA has applied the wrong rule and guide the discussion back to the right regulatory framework. Below are three common examples.

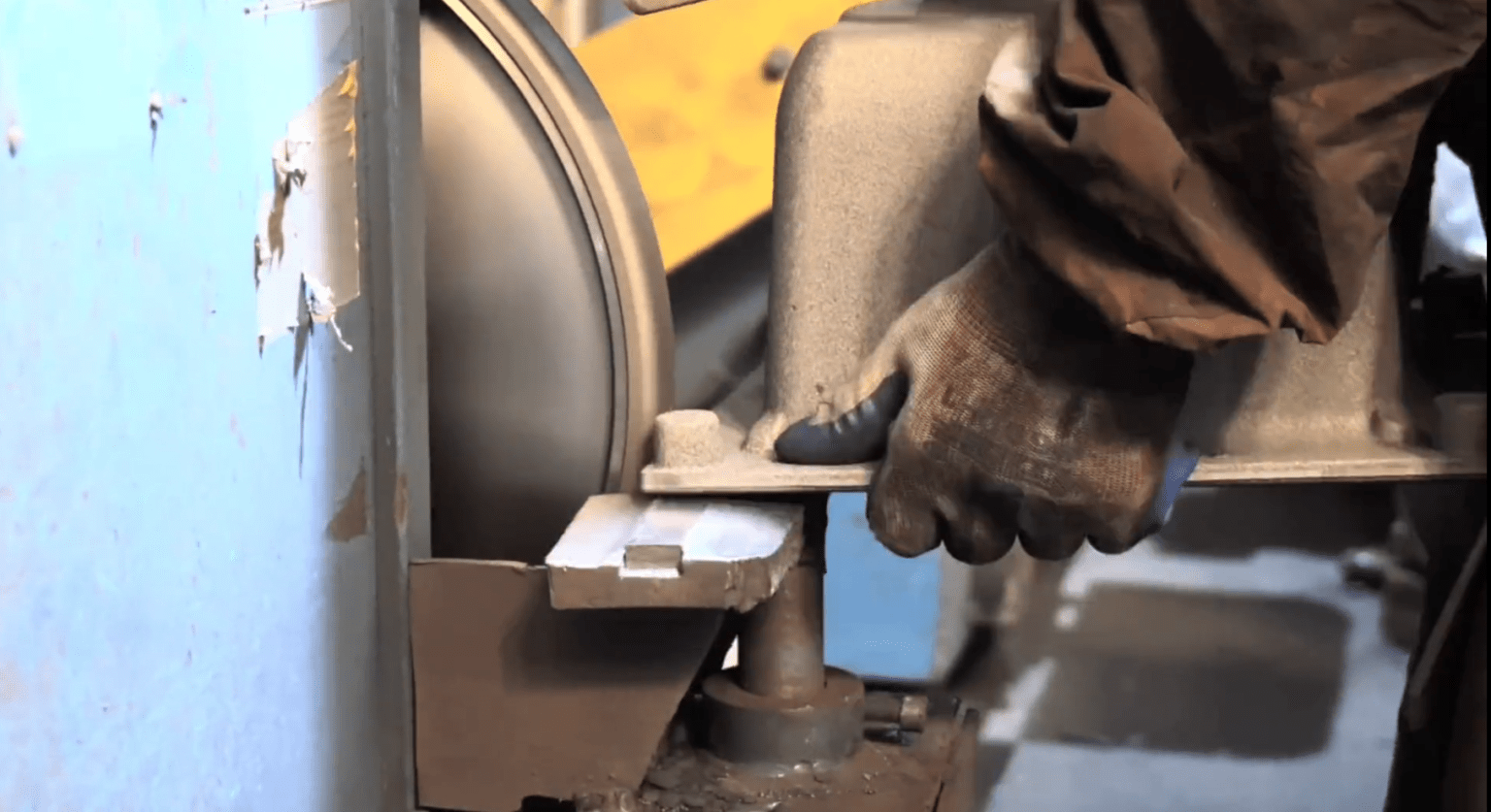

1) A “cut-off saw” isn’t a “saw”

On the shop floor, many refer to a fixed abrasive cut-off wheel as a “cut-off saw.” OSHA does not. According to 29 CFR 1910.215 (Abrasive Wheel Machinery), this equipment is treated as a stationary abrasive cut-off machine, subject to the guarding and angular exposure requirements for cutting-off wheels—not the woodworking or circular saw standards.

On the shop floor, many refer to a fixed abrasive cut-off wheel as a “cut-off saw.” OSHA does not. According to 29 CFR 1910.215 (Abrasive Wheel Machinery), this equipment is treated as a stationary abrasive cut-off machine, subject to the guarding and angular exposure requirements for cutting-off wheels—not the woodworking or circular saw standards.

-

Reference: 29 CFR 1910.215 – Abrasive wheel machinery.

-

Related OSHA Directive: STD 01-12-026 – clarifies angular exposure requirements for cutting-off wheels.

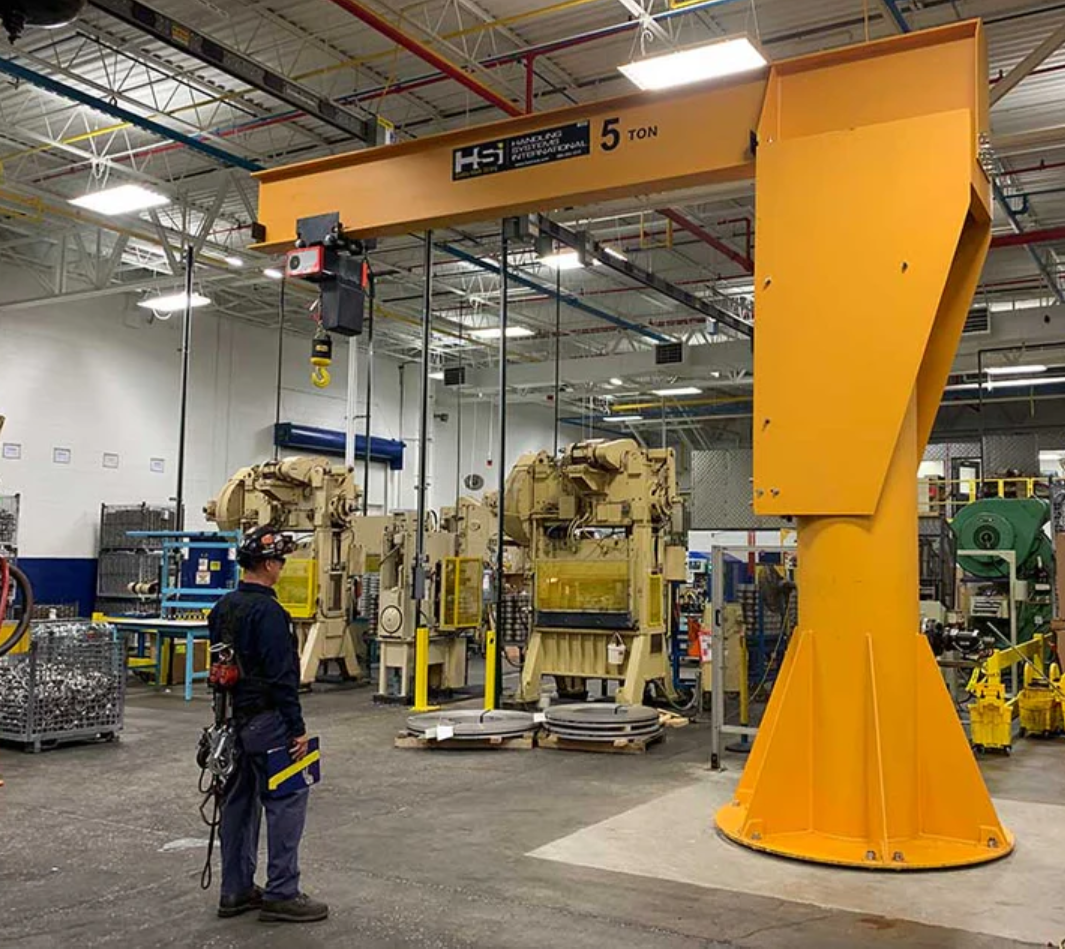

2) A "jib crane" isn’t a “crane”

Foundries commonly use the term “jib crane” for a rotating arm with a hoist. OSHA’s Overhead and Gantry Cranes rule (29 CFR 1910.179) is scoped to bridge and gantry cranes with trolleys traveling on fixed runways. Jib cranes, monorails, and overhead hoists don’t fit that definition.

Foundries commonly use the term “jib crane” for a rotating arm with a hoist. OSHA’s Overhead and Gantry Cranes rule (29 CFR 1910.179) is scoped to bridge and gantry cranes with trolleys traveling on fixed runways. Jib cranes, monorails, and overhead hoists don’t fit that definition.

OSHA confirmed this in a March 4, 1991 Letter of Interpretation: “This standard does not apply to underhung cranes, overhead hoists, or monorails.” In other words, while jib systems must still be inspected, maintained, and operated safely, 1910.179 does not govern them. Instead, applicable consensus standards such as ASME B30.11 (Monorails and Underhung Cranes) or B30.16 (Overhead Hoists) are the right references.

-

Reference: 29 CFR 1910.179 – Overhead and gantry cranes.

-

OSHA Letter of Interpretation (Mar. 4, 1991): Does 1910.179 apply to underhung cranes, hoists, and monorails?

3) A"belt grinder" isn’t a “grinder”

In foundries, fixed abrasive belt sanders are often described as “grinders.” OSHA makes a clear distinction. Section 1910.215(a)(5) specifically excludes coated-abrasive products (like sanding belts) from the abrasive wheel machinery standard. Instead, these machines fall under the general machine guarding requirements of 1910.212 and the mechanical power-transmission rules of 1910.219.

In foundries, fixed abrasive belt sanders are often described as “grinders.” OSHA makes a clear distinction. Section 1910.215(a)(5) specifically excludes coated-abrasive products (like sanding belts) from the abrasive wheel machinery standard. Instead, these machines fall under the general machine guarding requirements of 1910.212 and the mechanical power-transmission rules of 1910.219.

-

Reference: 29 CFR 1910.215(a)(5) – Excludes coated-abrasive products.

-

Related Standards: 29 CFR 1910.212 – General requirements for machine guarding and 29 CFR 1910.219 – Mechanical power-transmission apparatus.

-

OSHA Letter of Interpretation (Dec. 20, 1994): Machine guarding requirements under 1910.212.

Bottom line

The words we use in the foundry make sense to us—but OSHA doesn’t always hear them the same way. That can lead to inspectors applying rules that sound right but are out of scope. Foundry leaders don’t need to change their shop language, but they do need to know the distinctions so they can recognize when the wrong standard is being applied and ensure they are complying the appropriate and relevant OSHA regulations.

The words we use in the foundry make sense to us—but OSHA doesn’t always hear them the same way. That can lead to inspectors applying rules that sound right but are out of scope. Foundry leaders don’t need to change their shop language, but they do need to know the distinctions so they can recognize when the wrong standard is being applied and ensure they are complying the appropriate and relevant OSHA regulations.