Viking Wheel Blast Systems Launches the SD-MAX 1600

Viking Wheel Blast Systems Launches the SD-MAX 1600:

A Smarter, Stronger Blast Wheel for Heavy-Duty Performance

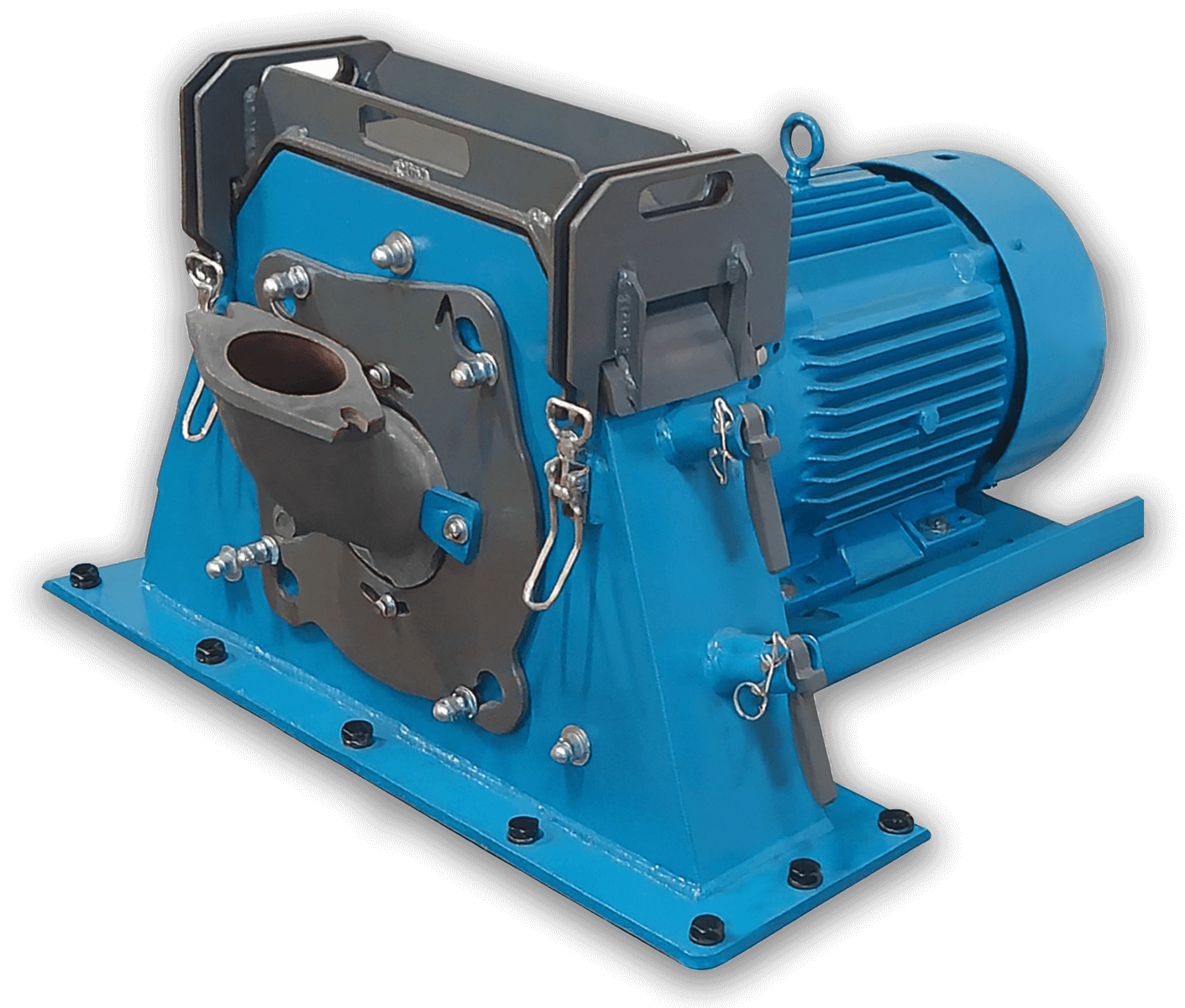

FOR IMMEDIATE RELEASE (Rose Hill, KS – September 2025) — Viking Wheel Blast Systems proudly announces the launch of its latest innovation: the SD-MAX 1600 Blast Wheel. Designed for exceptional durability, reduced maintenance time, and consistent blasting performance, the SD-MAX 1600 marks a major advancement in wheel blast technology.

This next-generation blast wheel delivers a powerful combination of precision engineering and operator-focused design, making it ideal for high-production environments in foundry, manufacturing, oilfield, and fabrication industries.

“The SD-MAX 1600 is the result of years of customer feedback and real-world field testing,” said Deron Lock, President at Viking Wheel Blast Systems. “We designed every component to maximize uptime, simplify maintenance without adding expensive gimmicks, and extend service life.”

Key Features of the SD-MAX 1600 Include:

- Quick-Change Blade Design – Reduces downtime during blade replacement

- Low-Vibration, Balanced Assembly – Extends the life of internal components

- The new housing design vastly eliminates cracking and motor damage, even when maintenance is neglected.

No gimmicks or features that add replacement parts and cost.

No gimmicks or features that add replacement parts and cost.- Bolts have been eliminated where possible to reduce shot locking of threads.

- Improved Maintenance Access – Simplifies service with safety-first features

- Blades: Precision cast special alloy for perfect fitment. The SD-MAX blades go through a series of treatment processes to increase blade life 1.5-2x over previous models, outlasting nearly every comparable wheel in the market.

- Precision cast special alloy liners – Longer-lasting protection with precise alignment

- A truly “toolless” design for securing liners. A spring-loaded lever holds the liners in place without the need to hammer in a wedge or tighten a bolt.

- The lid engages a spring-loaded pin to lock the lid open for safety and ease during liner replacement.

- Available in 16” or 15” diameters

Built to Maximize Performance

Every detail of the SD-MAX 1600 has been refined for long-lasting performance. From the precision-cast flat tapered blades with shot-release slots to the spring-loaded liner system that eliminates threaded fasteners, this wheel is built for fast service, rock-solid reliability, and superior blasting results.

Available Now

The SD-MAX 1600 is available as an upgrade to existing Viking machines or as part of new equipment orders. For customers currently running competitive blast wheels, Viking offers retrofitting options to bring the power of the SD-MAX 1600 to your operation.

About Viking Wheel Blast Systems

Viking is a U.S.-owned manufacturer of heavy-duty shot blast equipment, parts washers, and vibratory systems. Based in Rose Hill, Kansas, Viking serves the manufacturing, foundry, and industrial sectors with rugged, reliable equipment engineered for peak performance and backed by an unmatched commitment to customer service.

Media Contact:

Darick Parson

Marketing Manager

Viking Wheel Blast Systems

731 South Industrial Court

Rose Hill, KS 67113

Telephone: (316) 634-6699

Email: dparson@vikingcorporation.com

Website: vikingcorporation.com